Polished Concrete Brisbane

Introduction:

Polished concrete floors are a perfect choice for residential, commercial & industrial flooring. In high-visibility, high-traffic commercial spaces, such as retail stores, restaurants and salons, concrete floors are an ideal alternative to wood, vinyl tiles and carpet. Not only can they withstand more abuse than other flooring materials, they can also be customised in a way other floors can't. No surface in a building takes more abuse than the floor. This is especially true in industrial settings, whether it be a warehouse, production facility, educational or institutional setting, we can install a polished concrete floor or epoxy flooring system that will perform and outlast any other flooring solution. Contact us to discuss any polished concrete or epoxy flooring installation requirements or organise an obligation free quote around Brisbane or the Gold Coast.

Polished Concrete Floors:

Industrial Concrete Coatings Polished Concrete Systems are fast, economical, durable and easy to apply systems for polished concrete. Thanks to recent technical advancements and development, it is now possible to change standard concrete floors into hygienic, traffic and wear resistant, beautiful, polished floors that are easy to maintain. Due to the high performance of our Mechanically Polished Concrete (MPC) System, polishing and grinding of concrete is becoming more desirable in comparison to the use of other floor coatings and coverings.

Characteristics of a polished concrete floors:

|

Click here to see photos of concrete grinding & polished concrete floor jobs

We recommend the use of polished floors in a variety of applications that require a heavy traffic resistant,

clean and aesthetically pleasing flooring solutions.

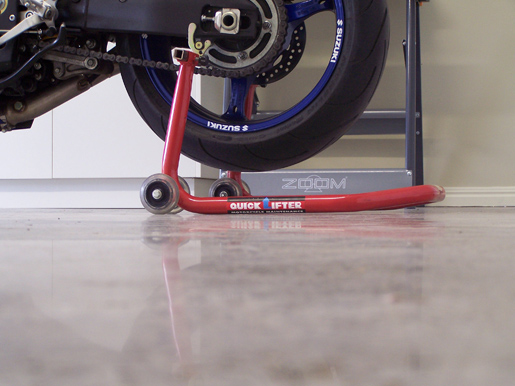

This may include warehouses, shops, supermarket, restaurants, garages, houses, showrooms, liquor stores and more.

We are the experts in hand polishing of furniture and walls, we can polish BBQ'S, Fireplace surrounds, Bench Seats, Columns,

Walls in-situ or Tilt panel or nearly any shaped concrete surface!

We have great rates, guaranteed quality work, fully QBCC licenced & insured professional tradesman.

We have smaller concrete grinding machines for domestic work.

As well as larger machines designed for larger industrial and commercial polished concrete floors & floor preparation jobs.

Concrete Grinding and Concrete Polishing Are Desirable Ways to Make a Floor Shine

Industrial Concrete Coatings are specialists in concrete polishing of concrete floors.

We see the benefits of concrete grinding, concrete polishing a floor or installing epoxy flooring in large commercial businesses

or public facilities by the extra reflectiveness reducing lighting requirements and minimising cleaning processes.

Polished Concrete that Shines

One of the first things customers see, whether they realise it or not, is the flooring in an establishment. It can make a big impression.

Giving an Old Floor New Life

Unfortunately, no surface in any structure will take on more abuse than the floor.

That is why polished concrete is done to transform the looks of a worn-out old floor and give it new life through concrete polishing.

The Beauty of Polished Concrete

A polished flooring system is a great floor to pick, it ensures that no shine is lost because of a large influx of traffic.

Some of our customers choose to include a polished concrete floor or epoxy coated floor inside high end residences.

Polished concrete can be less costly than other flooring options and people like the convenience and durability of a glazed concrete or epoxy flooring system.

Suitable Venues for Polished Concrete

Commercial property owners need to be ever aware of flooring systems that will keep their good looks, despite high foot traffic.

As noted, a polished concrete floor placed in a high-profile area will maintain its lustre and look great from one year to the next.

These highly resilient floors not only are suitable for residential, retail stores, public terminals and industrial venues,

they can also be used in large educational institutions and governmental facilities.

A Lasting Shine

Customising your flooring to make sure it is well-matched with the colours of the walls in the facility in which it will be installed.

What method is best for polished concrete?

Polished concrete is now used as a broad term that has come to include two methods, "Grind and Seal" which is a slightly cheaper

option where we grind to expose the stone in the concrete and apply a topical sealer to make the concrete sealed, dust free, shiny

and "Mechanically Polished Concrete" (MPC) or proper polished concrete we grind the surface much the same as we do

with Grind & Seal, but instead of applying a topical sealer we use diamond polishing pads to polish the stone and

cement itself much like the polishing process in that of marble or granite.

It is a high-end finish which can is dearer and can be glossier and smoother.

What finish is best for polished concrete?

Different finishes can be performed when polishing concrete depending on the customers desired look.

Generally we can offer Nil stone exposure(Surface Polish or Creme Polish), Minimal stone exposure, Salt and Pepper and Full stone exposure.

These results we can achieve are dependant on how the concreter has left the surface finished.

How much does polished concrete really cost?

Cost & life-cycle of the floor should be a major consideration here as you want to find a flooring product that lasts and looks good,

even when subjected to high volumes of foot traffic or the abuses that are associated with everyday wear and tear.

Is it cheaper to polish concrete or install epoxy?

This depends on a number of factors including the look you are trying to achieve, the condition of the existing concrete surface.

We can recommend the best option once we do our onsite inspection.

Diamond Grinding Floor Preparation:

Uplift Floor Coverings

We can remove vinyl, vinyl tiles, carpet, direct stick carpet, porcelain and ceramic tiles plus timber

and cork flooring and any glue or coatings the easy way.

Concrete Sub-Floor Preparation

We also grind to remove high spots, diamond grinding of rain affected slabs and can level a slab ready for new floor coverings.

Remove old glue & levelling floors

We also grind existing tile glue and remove the glue residue that is left over from taking up a carpet or similar flooring.

We can prep the sub-floor before the new flooring is installed and make sure the floor is levelled for the installation.

We are committed to installing concrete floors that not only shine but can recommend products that

take a lot of abuse and still remain looking great for years to come.

Servicing Brisbane , Gold Coast & Sunshine Coast

Get in touch - phone: 0492 131 276

email: pat@industrialconcretecoatings.com.au

|

|

QBCC Licence #:15250243

© Copyright 2002 - 2024 Industrial Concrete Coatings Australia Pty Ltd All Rights Reserved.